Standard interior power and free spray line

Standard interior power and free spray line

Standard interior power and free spray line

01Applicable product:

1 or 2 coats automotive interior products, UV paint and other needs Sprayed plastic products

02 Applicable size

According to the jigs size can be designed into 600*600mm-1000*1000mm

03Applicable capacity

Main design rhythm: Fixture step spraying operation:60-120s/ jig,

the chain speed can be designed to

1-5m/min,

Year base is 251 days 20 hours per day (two shifts)

Assume one jig put 10 pieces, the annual output of about 300,000

Actual production capacity is subject to product size.

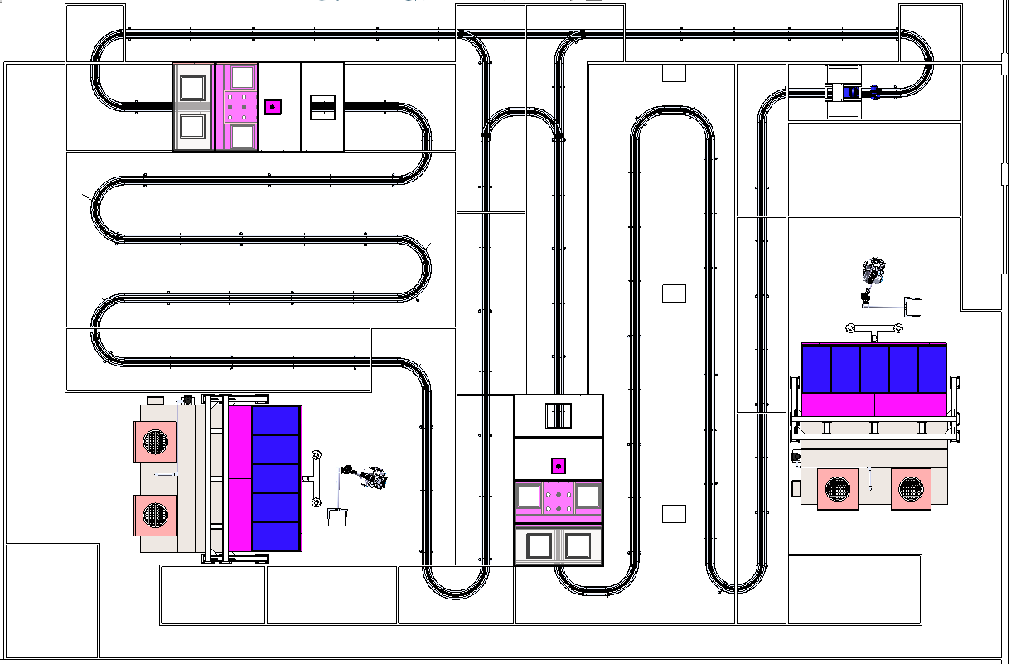

Standardized interior power and free conveyer Layout

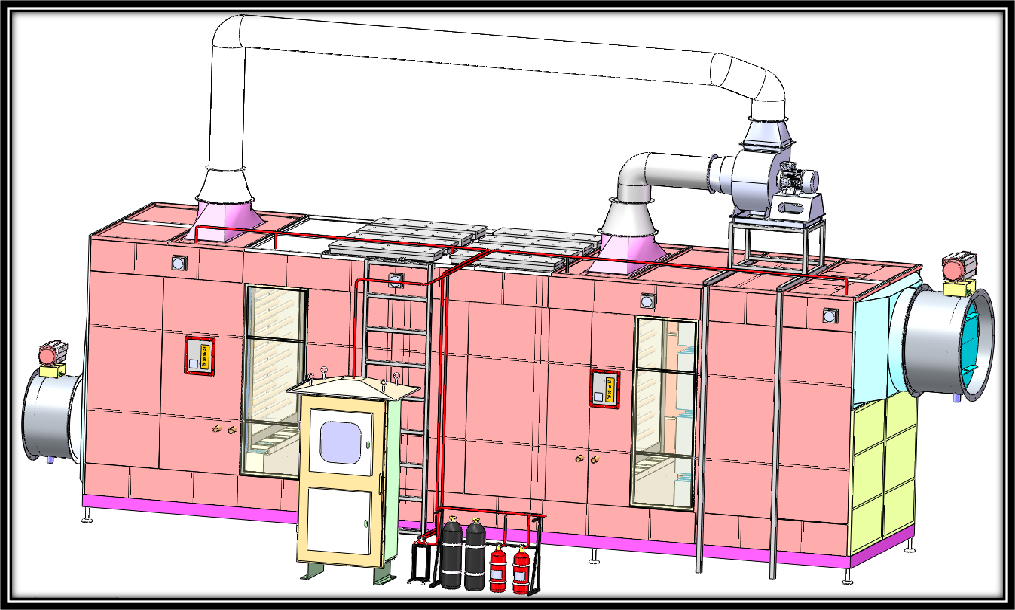

Standardized interior power and free conveyer 3D drawing

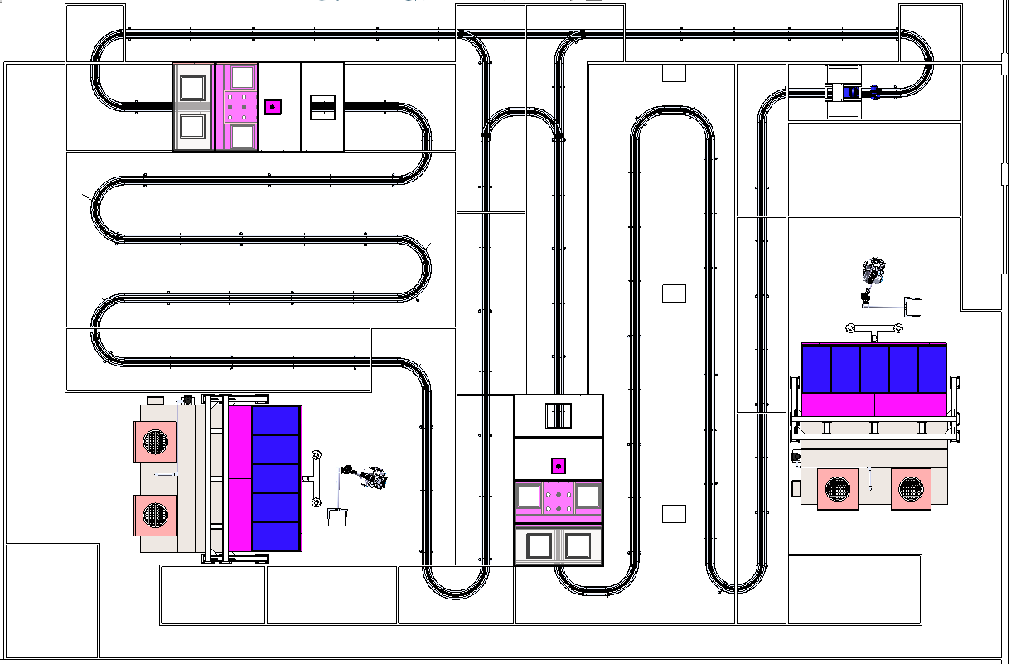

Standard interior line spraying process flow

Main Equipment's system list

Number | Equipment's List | Equipment's Brand | Equipment Type |

1 | 积放式输送链 Power and free conveyer | Jinker | Air switch - Delixi, Variable frequency drive - Delta, Motor if not additional specified all use Shanghai motor, Servo motor - Panasonic, Heating control - Delixi solid state relay, Pneumatic control -SMC, Keynes for sensors. |

2 | 静电/雪花清洗除尘 | Jinker | |

3 | 预热段 Preheat zone | Jinker | |

4 | 喷房/搬运室 Booth | Jinker | |

5 | 喷房供风空调系统 ASH | Jinker | |

6 | 机器人部分 Robot system | YASKAWA (Optional ) | |

7 | 供漆室/机器人控制 Paint circle system | Jinker | |

8 | 烘道 Oven | Jinker | |

9 | UV固化炉 UV bake | Jinker | |

10 | 设备平台 Platform | Jinker | |

11 | 废气处理系统 Emission system | Jinker | |

12 | 电器控制系统 Control System | Jinker | |

13 | 供排风管工程 Supply and exhaust duct works | By Customer |

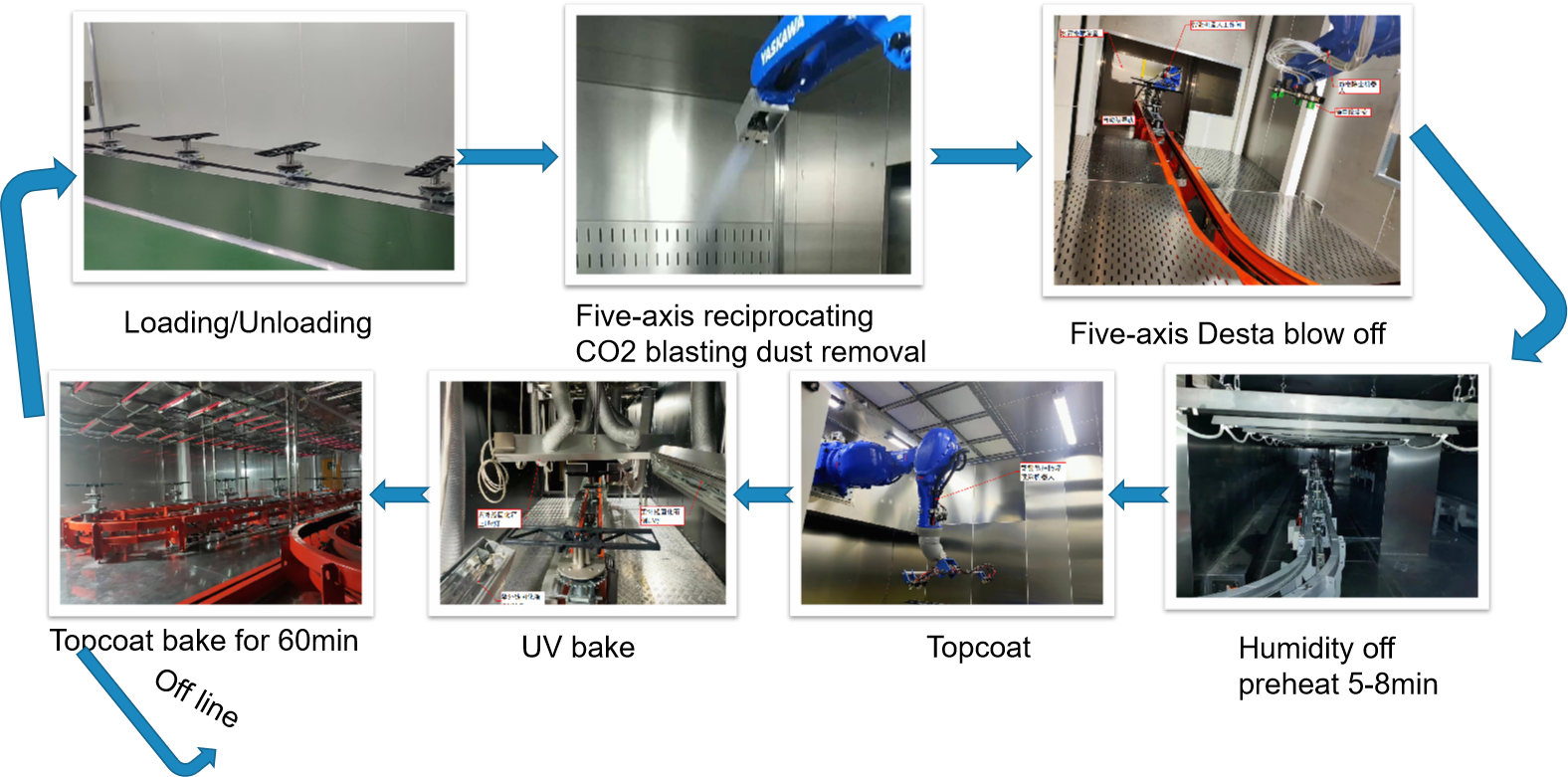

Key equipment :ASH Unit

Key equipment :Paint Robot YASKAWA MPX-1950

●The flexible layout can be placed on the ground, hung on the wall and installed upside down

●The robot wrist can carry a weight of 7 kg, although it is a medium-sized robot, it can carry multiple spray guns and spray cups comparable to large robots.

●The internal pressure explosion-proof structure with small air consumption is adopted

●By re-correcting the joint position of the robot (S/L unbiased), the area near the abdomen of the robot can be effectively utilized, and the sprayed object can be placed near the robot

Key Equipment :“O“ emission workstation

Main Process:

①VOC inlet concentration, temperature, PM value monitoring

②VOC dust filtration treatment

③ PM2.5/10 monitoring and filtering.

④Exhaust gas conditioning pretreatment, temperature, concentration, pressure early warning monitoring

⑤Secondary zeolite/activated carbon adsorption exhaust gas purification

⑥VOC gas phase liquefaction processing system

⑦VOC concentration/smoke sensing/PM monitoring.

⑧Air keep temp/humidity treatment

⑨Booth circulation

⑩Fire extinguishing system

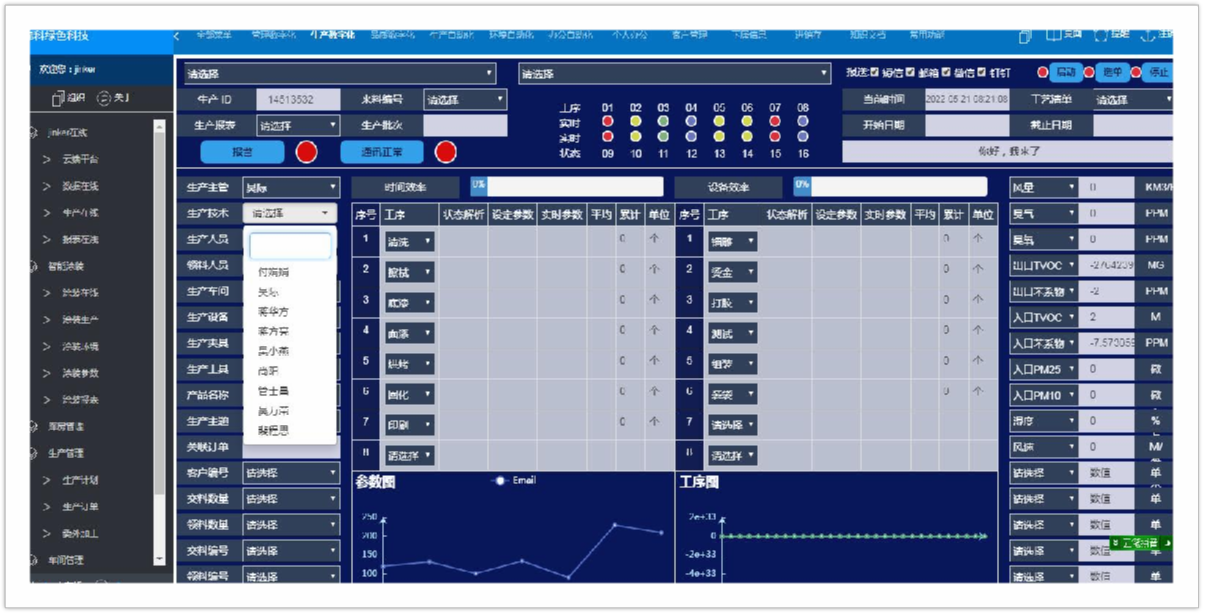

Key system :Digital communication system

The main function of digital production workshop/production line/workstation, the use of digital production cloud system platform, communication compatible with major brands of MES and EPR system interface, real-time production data traceability system.

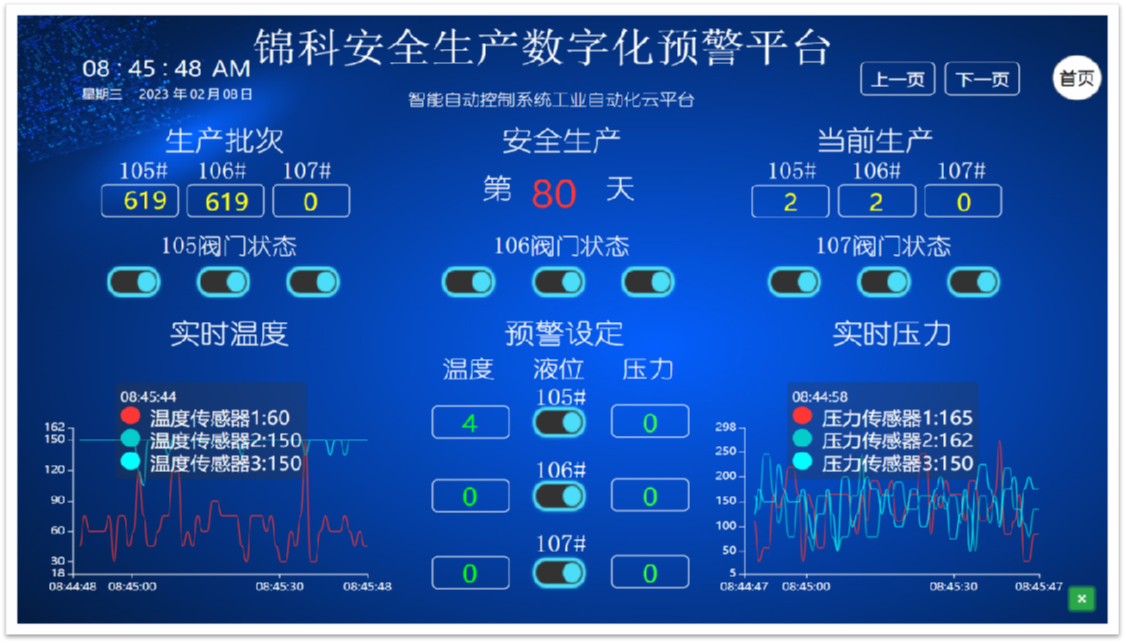

Key system :Digital cloud configuration

Safety production digital warning platform, on time monitoring of batch, safety production date, production quantity, on-time temperature/pressure/ liquid level status ,process parameters pick up base on customer’s design.

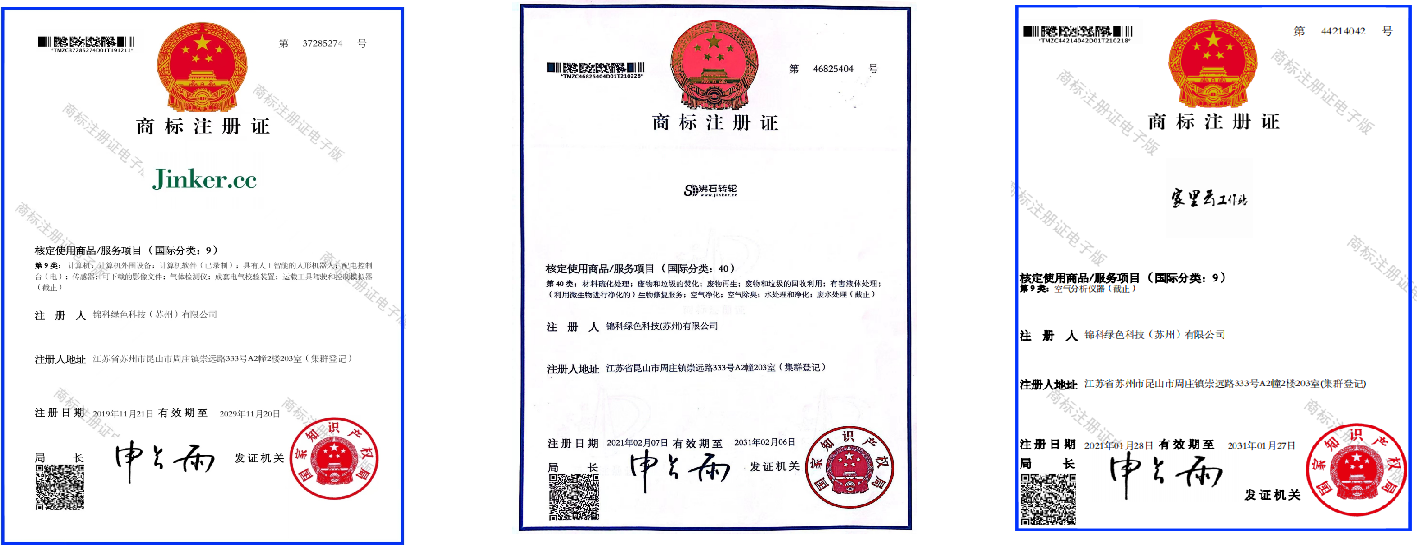

Jinke company profile

Jinke Green Technology (Suzhou) Co., Ltd. is a private science and technology enterprise in Jiangsu Province and a small and medium-sized science and technology enterprise in Jiangsu Province. In 2020, Jinke Green Technology (Suzhou) Co., Ltd. is selected as a national high-tech warehousing and cultivation enterprise. It is an integrated solution provider of non-standard industrial automation and industrial cloud system platform, mainly involved in the design and development of painting equipment, welding equipment, environmental treatment equipment and intelligent manufacturing equipment and technology. Manufacturing, installation and debugging, big data acquisition, storage, algorithm, analysis and control and the development of cloud information communication application software

Jinke company product line I

Jinke's main products are ecological environment digital workstation, digital intelligent painting workstation, digital robot painting production line, digital robot welding production line, digital waste gas treatment workstation, digital waste and sewage treatment workstation, digital air energy workstation, system industrial control workstation, smart home workstation, jinker information workstation, etc

Jinke company product line II

Jinke's main products are ecological environment digital workstation, digital intelligent painting workstation, digital robot painting production line, digital robot welding production line, digital waste gas treatment workstation, digital waste and sewage treatment workstation, digital air energy workstation, system industrial control workstation, smart home workstation, jinker information workstation, etc.

Thanks for your attention

Jinke Green Technology (Suzhou) Co., Ltd

Contact phone :(86)0512-57205360 13862632778

Working Station∶Monday to Friday 9∶00-18∶00

Contact person ∶Mr Jiang /Mr. Wu

Email∶ jinker@jinker.net

Address ∶333 Chongyuan Road, Zhouzhuang Town, Kunshan City, Jiangsu Province

Scan the code to follow the latest updates

Scan the code to follow the latest updates Contact:Miss Jiang

Mobile:+8613862632778

Email:jinker@jinker.net

Address:333 Chongyuan Road, Zhouzhuang Town, Kunshan City